A new lightweight, three-dimensional structure developed by researchers enhances lithium ion transport in batteries, showing improved stability and energy density, with potential for industrial application.

A new three-dimensional polymeric structure developed by POSTECH and KIER researchers significantly enhances lithium ion transport and battery performance, showing great promise for future commercialization.

Just as road signs guide travelers with directions and distances to prevent them from losing their way, “signposts” in certain contexts offer similar guidance. Recently, in the field of chemistry, structures that fulfill a comparable role have been identified, sparking considerable interest in the academic community.

Professor Soojin Park and Dong-Yeob Han, a PhD candidate, from the Department of Chemistry at Pohang University of Science and Technology (POSTECH)

Advances in Battery Technology

Battery technology used in electronic devices such as electric vehicles and smartphones continues to evolve. Notably, lithium metal anodes have an energy capacity of 3,860 mAh/g, more than ten times that of currently commercialized graphite anodes. Lithium metal anodes can store more energy in a smaller space and, unlike graphite or silicon, can directly participate in electrochemical reactions as electrodes.

However, during the charging and discharging process, the uneven distribution of lithium ions creates areas known as “dead Li,” which reduces the battery’s capacity and performance. Additionally, when lithium grows in one direction, it can reach the cathode on the opposite side, causing an internal short circuit. Although recent research has focused on optimizing lithium transport in three-dimensional structures, most of these structures rely on heavy metals, significantly compromising the battery’s energy density per weight.

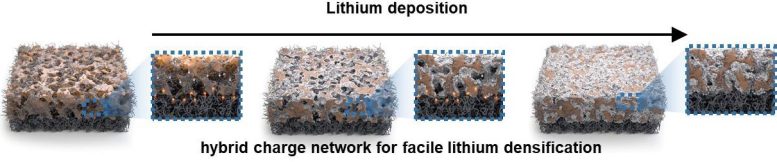

Schematic representation of the internal geometry of the hybrid structure after lithium electrodeposition. Credit: POSTECH

Innovative Three-Dimensional Structure for Anodes

To address this issue, the team developed a hybrid porous structure using polyvinyl alcohol, a lightweight polymer with a high affinity for lithium ions, combined with single-walled carbon nanotubes and nanocarbon spheres.

This structure is more than five times lighter than the copper (Cu) collectors typically used in battery anodes and has a high affinity for lithium ions, facilitating their migration through the spaces in the three-dimensional porous structure and enabling uniform lithium electrodeposition.

In experiments, lithium metal anode batteries incorporating the team’s three-dimensional structure demonstrated high stability after over 200 charge-discharge cycles and achieved a high energy density of 344 Wh/kg (energy to total cell weight). Notably, these experiments were conducted using pouch cells, which are representative of actual industrial applications, rather than lab-scale coin cells, highlighting the technology’s strong potential for commercialization.

Professor Soojin Park of POSTECH expressed the significance of the research by stating, “This research opens up new possibilities for maximizing the energy density of lithium metal batteries.” Dr. Gyujin Song of the KIER emphasized, “This structure, which combines lightweight properties with high energy density, represents a breakthrough in future battery technology.”

Reference: “Facile Lithium Densification Kinetics by Hyperporous/Hybrid Conductor for High-Energy-Density Lithium Metal Batteries” by Dong-Yeob Han, Saehun Kim, Seoha Nam, Gayoung Lee, Hongyeul Bae, Jin Hong Kim, Nam-Soon Choi, Gyujin Song and Soojin Park, 22 April 2024, Advanced Science.

DOI: 10.1002/advs.202402156

The research was conducted with support from a project of the Ministry of Science and ICT.